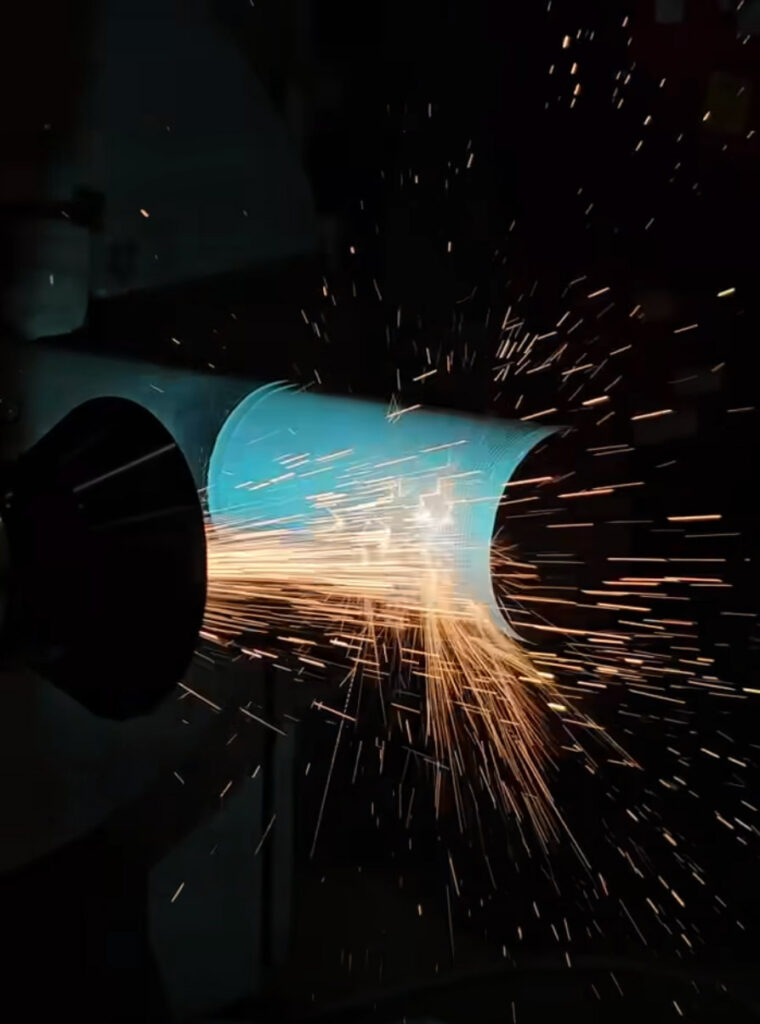

METAL SPRAYING

Fusion technology, putting your business a step ahead.

Metal Spraying is . . .

… a specialised surface coating process that is used to enhance properties such as corrosion and wear resistance, heat tolerance and electrical conductivity. It is also commonly applied for repair and salvage purposes.

At Werner Engineering, we primarily use metal spraying to restore shafts by building up layers of metal to repair surface damage. Our qualified tradesmen expertly carry out this process in-house, using heat and powder and applying the metal in precisely measured amounts. Afterwards, our skilled machinists finish the product by machining and grinding it to achieve a high-quality surface that looks and performs like new.

- Hot powder flame spraying

- Repairs to seal areas, bearing journals, pumps, shafts etc.

- Almost any material and any size can be coated/sprayed

- Flexible operation

- Corrosion protection