Werner’s commitment to the planet – all of us

In December 2015 Werner Engineering were approached by Carbon Friendly Enterprises (CFE), a local indigenous owned and run business, about an Energy Audit & Energy Efficiency Opportunities Site Assessment, offering to look into our electrical issues plus shed light on Werner’s energy consumption.

Since moving to our new workshop in Paget at the end of 2013, we had been plagued by circuit boards burning out and other electrical problems, causing frequent downtime and affecting our operations and delivery schedules.

It took some convincing but eventually we decided to place our trust in CFE and gave them the green light.

The first step was to perform a detailed load profiling assessment which revealed several things about our company and the way we operated as well as the underlying ‘harmonic’ and ‘dirty’ power issues that caused our high value assets to fail. As explained by CFE, electronic parts do not wear out, they burn out and this was at the bottom of our problems at the time.

Having identified the cause, they worked with us to provide a permanent fix, using state of the are power management equipment and verifying the results.

To date we have gone from a position of high exposure to almost zero breakdown downtime due to electronic/electrical failure. This gives us and our customers confidence and ensures that we can be relied upon to deliver a high-quality product – on time, every time.

Our Journey

… to becoming a registered power station

Taking a long-term staged approach, we viewed this as an opportunity to demonstrate our ongoing commitment to improving our operation and reducing our carbon footprint.

The 5 stages of the carefully planned approach

STAGE 1

- Harmonic Mitigation & Power Factor correction

STAGE 2

- Intelligent Lighting Upgrade to Led

- Tariff Renegotiation

- Air Compressor & Air Conditioner

management - Hot Water temperature adjustment

STAGE 3

- 63.6kW Solar System installation

STAGE 4

- 82kW Solar System installation

STAGE 5

- Register as a Power Station

- Export Power

- Become a Carbon Neutral Workshop

The details

STAGE 1: Harmonic Mitigation & Power Factor Correction

Power Factor Correction

- Install state of the art Intelligent Power Conditioning and Phase Balancing

- Energy savings of 14% and reducing load on the grid network

- Measured power factor was 0.65 to 0.794

What is Power Factor?

Power Factor is the ratio of real power to apparent power. The closer the power factor comes to unity, the more effectively the site electricity is being utilised. Power factors of greater than 0.9 are considered good. The simplest way to explain power factor is the coffee analogy located on the right.

Active Harmonic Mitigation

Install state of the art Active Harmonic Mitigation, protecting our high-value electronic and electrical assets and saving on costly repairs and maintenance.

- Estimated savings in the hundreds of thousands

Fig 1. Power Factor Analogy

STAGE 2: Upgrades

A whole raft of measures which brought us step by step closer to becoming a registered power station. The lighting upgrade alone translates to a reduction of 108,372kWh that equates to 88 tons of CO2 reduction from the atmosphere annually.

State of the Art Intelligent Lighting Upgrade to LED

Energy savings of up to 80%, providing a safer environment by not exposing our workers to the risks of arc lighting, reducing environmental contamination and load by not using lamps made of toxic heavy metals that are costly to produce and dispose of.

Tariff renegotiation

Energy savings of 8% achieved.

Air Compressor and Air Conditioner Management

Resulted in energy savings of 5%.

Hot Water Temperature Adjustment

Energy savings of 1.5% achieved.

STAGE 3: First Solar System Installation

JANUARY 2017 – STAGE 3

63.6kW Solar System

- Generating a projected 102,841kWh annually

- Reducing C02 emissions by 84.9 metric tons annually

- Moving Werner Engineering towards the goal of being a carbon neutral company

Results:

- Full implementation by January 2017

- Resulted in 50% electrical bill reduction in the first year

- An estimated 70% reduction from year 5 onwards

- Actual production of 207,145kWh per annum, far exceeding expectations that translates into 171 ton of CO2 not entering the atmosphere annually

63.6kW Solar Project – Stage 3 of Werner Engineering’s Energy Management Plan

STAGE 4: Second Solar System Installation

MARCH 2020 – STAGE 4

63.6kW Solar System

- Following the successful completion of Stages 1 to 3, we have now completed Stage 4 (March 2020) and installed an additional 82kW solar system to offset rising energy prices

- Projected maximum production is at 300,000kWh

Results:

Until now, the 63.3kW solar installation alone has produced enough to power 25 homes for one year, 25 passenger cars to drive for one year, 205 barrels of oil and is equivalent to 2422 tree seedlings planted. Actual production of the new 82kW system generates 88,662kWh (computer controlled to produce only what we consume with no excess) equates to an additional 72.7 metric tons of CO2 not entering the atmosphere per annum. Enough to power 10.9 homes for one year, this equals 145 barrels of oil or 13.3 passenger vehicles driven for one year.

This new direction for Werner Engineering and our carefully planned energy solutions ensure we save on our bottom line. An investment that is working in reverse, saving us money by reducing a major overhead and helping the environment at the same time.

CFE as a specialist Energy Efficiency Company with a mining background looked at our site as a whole rather than giving us a band-aid solar solution. They had the skills and technical know-how to not only provide the right solution from the start but have the vision to plan ahead so each subsequent energy efficiency upgrade dovetailed neatly into what had already been achieved.

Pictorial Representation of Stage 4 (82kW Solar System),

installed in March 2020

Stage 4 Solar Panels

STAGE 5: Accreditation

APRIL 2020 – ACCREDITATION

- Registering as a Power Station

- Export Power

- Become a Carbon Neutral Workshop

The combined output for both solar systems of 155kW allowed Werner Engineering to apply and become an accredited ‘Green’ Power Station. This enables Werner to sell excess power generated back into the grid and supports us towards the goal of becoming not only carbon neutral but carbon positive, sell green power to other businesses and set up a charging station for electric cars.

Application forms have been lodged for the approval to sell power back to the grid.

Accreditation of power station – WERNER-SOLAR w SGU-QLD (Approved 16 April 2020)

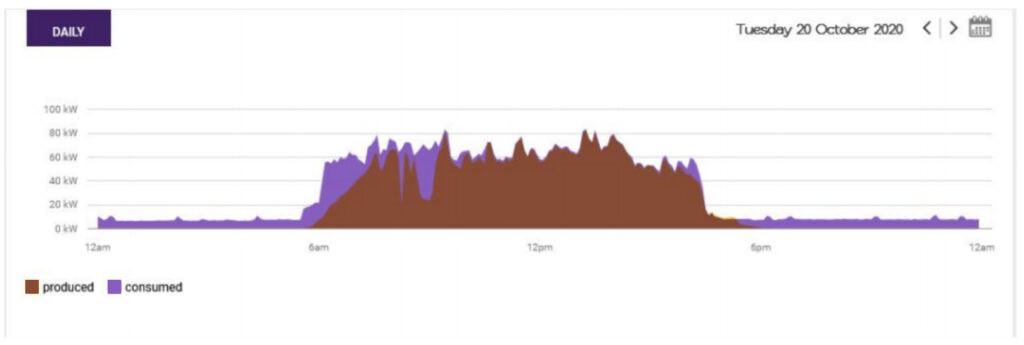

The graph above shows what our goal was and what we have achieved.

These are actual figures from Tuesday, 20th of October 2020 on our consumption of power versus production of power. In purple is our power usage and in brown is the solar power production. We started work at 6.00am and finished around 4.30 – 5.00pm on this day. Purple shows what we purchased from the power grid that was not covered by solar production, i.e. the brown. At 6.00 am the sun was still low and the solar still ramping up, the gap around 10.00 am was heavy cloud coverage reducing the solar production but nonetheless still producing power.

The combined result of Stages 1 – 4 has seen our electricity bill slashed by 75-80% while still expanding and growing the business, at the same time dramatically reducing our carbon footprint and becoming a carbon neutral business. Once approved to sell excess green power back into the power grid, Werner Engineering will be carbon positive – something we never dreamed of let alone achieve.

What’s next?